Evaporation Capacity: 0.3-5.6t/h

Moisture content after drying: 12-15%

Rotating Spped: 5-10r/min

Gradient: 3-5°

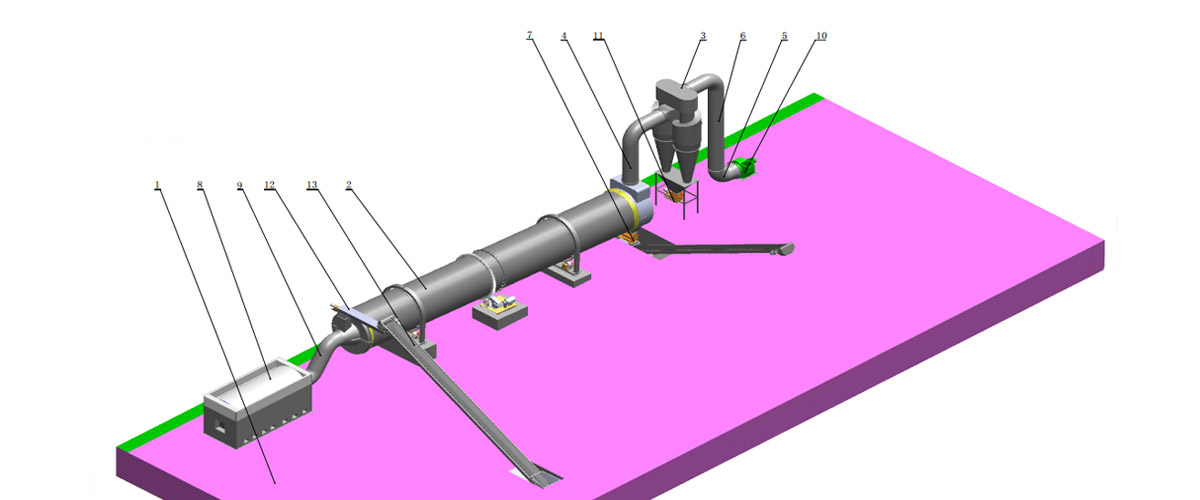

The rotary dryer is mainly composed of a cylinder, roller ring, base stopper and tail dust removal deive and other components.

It adopts low-speed rotation, bending plate hammering to disperse the material; according to the different characteristics of the material, different types of lifting plates and anti-sticking measures are adopted, so that the high-temperature airflow is mixed with the material, achieving a uniform drying effect.

Mainly used for the drying various biomass materials, suitable for dye plants, fertilizer plants, chemical plants, pharmaceutical plants and other manufacturers.

| Model | Power(kw) | Evaporation Capacity(t/h) | Inner Temperature | Outlet Temperature |

| YGHGφ1.2*12*1 | 5.5+15+2.2+1.5 | 0.3-0.6 | 300-500℃ | 90-100℃ |

| YGHGφ1.5*12*1 | 11+18.5+3+2.2 | 0.47-0.91 | ||

| YGHGφ1.5*18*1 | 11+30+3+2.2 | 0.7-1.34 | ||

| YGHGφ1.8*18*1 | 18.5+37+3+2.2 | 1-1.9 | ||

| YGHGφ1.8*24*1 | 18.5+55+3+2.2 | 1.35-2.44 | ||

| YGHGφ2.0*18*1 | 18.5+55+5.5+2.2 | 1.25-2.3 | ||

| YGHGφ2.0*24*1 | 18.5+75+5.5+2.2 | 1.67-2.9 | ||

| YGHGφ2.2*18*1 | 22+55+5.5+2.2 | 1.51-2.68 | ||

| YGHGφ2.2*24*1 | 22+90+5.5+2.2 | 2.02-3.36 | ||

| YGHGφ2.5*18*1 | 22+90+3+3 | 1.96-3.32 | ||

| YGHGφ2.5*24*1 | 22+90+5.5+3 | 2.61-4.16 | ||

| YGHGφ2.8*18*1 | 22+90+5.5+3 | 2.45-4 | ||

| YGHGφ2.8*24*1 | 22+132+5.5+3 | 3.27-5 | ||

| YGHGφ3.0*18*1 | 30+110+5.5+3 | 2.82-4.39 | ||

| YGHGφ3.0*24*1 | 30+160+5.5+3 | 3.76-5.6 |

1. High thermal efficiency. high contact surface between the material and hot air.

2. Reasonable structural design, easy to maintenance.

3. The design of the lifting plate in the cylinder is multi-angle, suitable for various materials.

4. Integral spiral rigid structure, won't deform under long-term high temperature

5. Compliance with various dust and emission regulations

6. Intelligent PLC control system, saving labor

Rotary dryer applies for a variety of materials, such as wood chips, wood shavings, sawdust, straw, rice husk, peanut shell, bagasse, grass, alfalfa, efb fiber etc.

1. Rotary Dryer Base 2. Rotary Dryer 3. Cyclone 4. Pipe 5. Fan Blower Dialectal Switching 6. Pipe 7. Air Lock 8. Stove

9. Connecting Pipe between stove and dryer 10. Fan Blower 11. Air Lock 12. U-shaped Conveyor 13. Belt Conveyor

Q: Are you manufacturer or trading company?

Q: I am newer to biomass industry, how to design suitable pellet plant?

Q: How to prepare for setting up a wood pellet production line?

Q: How can you guarantee the after-sales service?

Q: Are there some machines in my area I can observe?

Q: What type of raw materials can be pelletized by RotexMaster pellet machine?

Q: How to confirm the compression ratio of mould for my raw material?

Q: What is the main process for making biomass pellets?

Q: What is your work flow if we order Rotexmaster equipment?

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.