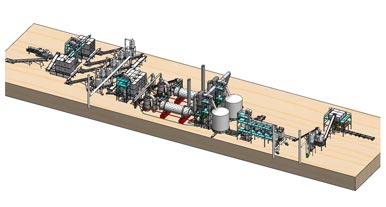

As a professional wood pellet production line manufacturer, we are well aware of the importance of the shipping process to customer experience. Our services include scheme design, raw material testing, equipment production, quality inspection, goods delivery, installation and commissioning, and subsequent technical support. In recent days, our delivery team has been focusing on helping our Thailand customer deliver the wood pellet production line. This is a complete 5 ton per hour wood pellet production line. After many investigations, the customer finally chose us. The customer said that we made them feel trusted.

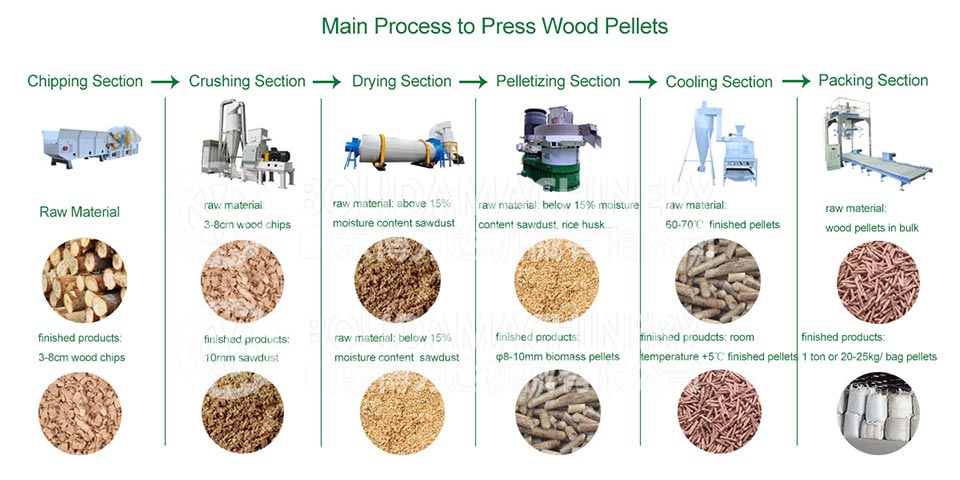

The raw material of this customer is waste wood and the moisture content is about 40%. We designed the project according to the customer's factory diagram, raw material conditions and some special requirements of the customer. This 5 ton per hour biomass pellet production line includes chipping section-crushing section-drying section-pelleting section-cooling section-packaging section-other auxiliary sections.

Our goal is to provide customers with high-quality biomass pellet production lines and excellent services. Through a refined delivery process, we ensure that every equipment can arrive at customers’ site smoothly and safely. Looking forward to working with you to jointly promote the development of renewable energy!

Biomass pellets to produce green methanol

What raw materials can be used to make biomass pellets in Indonesia

Mar. 21, 2025

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log