As the global demand for renewable energy grows, biomass pellets are gradually gaining attention as a sustainable energy source. Biomass pellets are made from renewable resources such as agricultural waste and forestry residues, and are environmentally friendly and renewable. In recent years, scientists have discovered a method to make green methanol from biomass pellets, injecting new vitality into the field of renewable energy.

Green methanol, as a clean alternative energy source, has a wide range of application prospects. It can be used as a fuel to replace traditional petroleum-based methanol and reduce greenhouse gas emissions; at the same time, it can also be used as a chemical raw material to produce various chemicals. The use of biomass particles to make green methanol can not only realize the resource utilization of waste, but also reduce dependence on traditional energy, with significant environmental and economic benefits.

The process of making green methanol from biomass pellets mainly includes the steps of pretreatment, gasification, and synthesis of biomass pellets. First, the biomass pellets need to be pretreated by crushing and drying to improve their gasification efficiency. Then, through the gasification reaction, the biomass pellets are converted into synthesis gas, which contains gases such as carbon monoxide and hydrogen. Next, the carbon monoxide and hydrogen in the synthesis gas are used to carry out the methanol synthesis reaction through the action of the catalyst. Finally, after treatment such as distillation, green methanol with higher purity is obtained.

In the process of making green methanol from biomass pellets, the choice of catalyst is crucial. Suitable catalysts can improve the efficiency of methanol synthesis and reduce energy consumption and costs. Currently, scientists are committed to developing efficient, stable and environmentally friendly catalysts to promote the further development of green methanol technology from biomass pellets.

In addition to the research and development of catalysts, the promotion and application of green methanol production technology from biomass pellets also faces some challenges. First, a sound system needs to be established for the collection, transportation and storage of biomass pellets to ensure their stable supply. Secondly, by-products such as tar and ash produced during the gasification of biomass pellets need to be effectively treated to avoid pollution to the environment. In addition, the cost and market competitiveness of green methanol production from biomass pellets are also factors that restrict its development.

In response to these challenges, the government and enterprises need to increase investment and R&D efforts to promote the innovation and application of green methanol technology made from biomass pellets. On the one hand, the government can introduce relevant policies to encourage the collection and use of biomass pellets and provide financial support and technical guidance; on the other hand, enterprises can strengthen cooperation with scientific research institutions to jointly develop efficient and environmentally friendly green methanol technology made from biomass pellets to improve product competitiveness and market share.

In addition, the public's awareness of renewable energy and environmental protection is also an important force in promoting the development of green methanol technology from biomass pellets. Through publicity and education, more people can understand the significance and value of green methanol from biomass pellets, and promote its widespread application in social life.

In summary, as a sustainable way of energy utilization, the production of green methanol from biomass pellets has broad application prospects and huge development potential. With the continuous advancement of technology and the continuous expansion of the market, it is believed that it will play an increasingly important role in the future energy field and contribute to the sustainable development of human society.

Full analysis of raw materials for biomass pellets in Thailand

Mar. 21, 2025

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

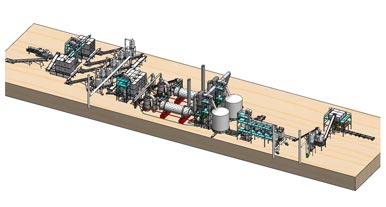

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log