As an important economy in Southeast Asia, Thailand has shown great potential in the field of renewable energy. Among them, the biomass pellet industry is gradually becoming an important part of the country's energy transformation. Thailand has abundant raw materials for biomass pellets. These resources are not only huge in quantity, but also have the advantages of low price and environmental protection, which provides a solid foundation for the production of biomass pellets.

1. Crop waste: high-quality raw materials for biomass pellets

Sugarcane bagasse

Thailand is the world's major sugarcane producer and sugarcane sugar exporter, and its sugarcane plantations are mainly distributed in the northeast, central and northern regions. Every year, a large amount of sugarcane bagasse is produced in the process of sugarcane sugar making, and these wastes are important raw materials for making biomass pellets. Sugarcane bagasse has the advantages of high fiber content and moderate calorific value. After proper treatment, it can be made into high-quality biomass pellets for power generation, industrial boiler fuel and other fields.

Cassava stems

Thailand is one of the world's largest cassava producers and exporters, and cassava planting areas are mainly concentrated in the northeast, north and central regions. As the main material for making biomass pellets, cassava stems have the advantages of high yield and rich fiber content. Biomass pellets made from cassava stems have the characteristics of high calorific value and low ash content, and are a high-quality renewable energy source.

Rice husks and rice straw

As Thailand's main food crop, the large-scale planting and harvesting of rice produces a large amount of rice husks and rice straw. These wastes are not only large in quantity, but also have the advantages of low price, small size, and low moisture content. They are high-quality raw materials for biomass pellet production. Biomass pellets made from rice husks and rice straw have a high calorific value when burned, and the ash after burning can be returned to farmland as fertilizer to achieve resource recycling.

Corn stalks and corn cobs

Thailand grows corn in a wide area, and corn stalks and corn cobs are also potential raw materials for biomass pellets. Corn stalks have a high fiber content and can be made into biomass pellets after processing for use in power generation, heating and other fields. Corn cobs have the characteristics of high hardness and not easy to break. When mixed with other raw materials, they can improve the strength and durability of biomass pellets.

2. Forestry waste: another important source of biomass pellets

Wood processing residues

Thailand has rich forest resources. Sawdust, wood chips and other wastes generated during wood processing can be processed into high-quality wood biomass pellets. These wood pellets have the advantages of high calorific value and low moisture content, and are suitable for various biomass combustion equipment.

Empty fruit bunches (EFB)

As a major palm oil producer, Thailand produces a large amount of EFB every year. This waste has the advantages of high calorific value and low price. It is a high-quality raw material for biomass pellet processing, and its processing technology is relatively mature. EFB pellets have good combustion characteristics and environmental protection performance, and are an ideal renewable energy source.

Thailand's abundant biomass pellet raw materials provide a solid foundation for the country's biomass pellet industry. With the continued growth of global demand for renewable energy, Thailand's biomass pellet industry is expected to usher in greater development opportunities and make important contributions to the country's economic development and energy transformation.

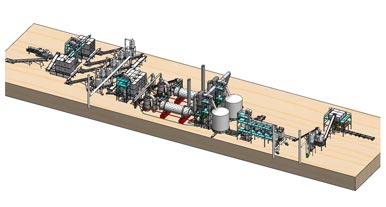

As leading supplier of biomass wood pellet machine in China, we Bolida&Rotexmaster can provide the whole biomass pellet production line equipment from design, manufacturing, delivery to installation guide, debugging and training. Welcome to consult us for designing your wood pellet plant.

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline

Mar. 21, 2025

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log