Recently, many customers have inquired about the cost of a biomass wood pellet production line in detail. This is really hard to say. It depends on the moisture of the raw materials and the required output to determine the model of wood pellet machine equipment required and other auxiliary equipment to match. All equipments serve raw materials, and inquiring about raw materials is a key step in making wood pellets. Crop straws, including the residues after harvesting, as well as the wastes after processing agricultural products, various waste woods, wood pallets, building templates, etc., are very rich renewable biomass resources.

Features of RotexMaster biomass wood pellet machine:

1. Spindle smoothness: The gearbox oil is used for smoothness, which plays a sufficient smoothing role while reducing the temperature of the spindle.

2. Roller bearing: During the whole operating cycle of the pressure roller, you can choose the method without oil injection and bearing replacement. You can also choose to control the oil injection method at any time according to the oil pressure, both of which have their advantages and disadvantages. Reasonable switching according to the customer's application address and method is more humane.

3. The gearbox transmission is enhanced

The whole machine adopts parallel helical gear transmission, with good tooth fit.

Helical gears with hard-toothed surfaces are used in the reduction box, the gear surface is widened, the gear module is increased, the gear coincidence is large, the load of each pair of gears is reduced, the bearing capacity of the gears is improved, and the strength of the gears of the traditional reduction box is increased by 5 -10 times.

The lubricating oil of the gearbox adopts the bypass water cooling system equipment to prevent the oil temperature from being too high and greatly enhance the service life of the internal bearing.

The failure rate is lower than the traditional reducer.

Assuming that you are interested in environmental protection projects and want to participate in wood pellet making projects, please feel free to contact us. We have a professional engineer team, CNC system, international sales team, after-sales service team, quality-inspection team, delivery team, proficient in biomass wood pellet production lines, and our product experts will configure the best solution for each customer. Please contact us by email, whatsapp or filling form on website, we can reply you as soon as possible.

Mar. 21, 2025

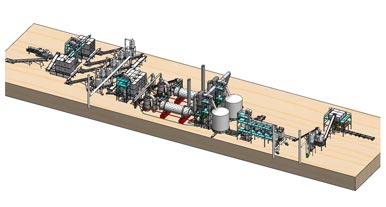

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log