As the global demand for renewable energy continues to grow, biomass pellets, as a clean energy alternative to fossil fuels, have become a hot commodity in the international market. Building medium and large scale biomass pellet plants can not only meet market demand, but also reduce costs and improve competitiveness through large-scale production. For investors who are interested in entering this field, building a medium-sized and large-scale biomass pellet plant is a complex but promising project. This article will provide you with a detailed introduction to the core steps and practical suggestions for building such a biomass pellet plant:

1. Project Preliminary Planning and Preparation

(1).Market research and feasibility analysis: Before deciding to build the biomass pellet production line, it is essential to have an in-depth understanding of the target market’s biomass pellet demand, price trends, competition, and policy support. Through detailed market research and feasibility analysis, the potential benefits and risks of the wood pellet plant project can be evaluated to provide a basis for subsequent decision-making.

(2).Factory site selection strategy: Choosing a suitable site is the basis for the success of the project. The ideal site should meet the following conditions:

Close to the raw material supply area, such as forest farms, agricultural production areas, etc., to reduce transportation costs; convenient transportation, easy to input raw materials and output finished products;

Comply with local environmental protection and land use planning to avoid trouble in later approval and operation.

Infrastructure support: It is necessary to ensure the height of the factory building (recommended ≥10 meters), power supply stability and sewage discharge capacity to avoid increasing costs for later transformation.

(3).Raw material supply guarantee: Ensuring a stable supply of raw materials is the key to the continued operation of the biomass pellet plant. Establish long-term cooperative relations with local forestry departments, agricultural cooperatives or related enterprises, sign raw material supply contracts, and ensure the quantity, quality and price stability of raw materials.

(4).Transformer: The biomass pellet production industry consumes a lot of electricity. After determining the production capacity, choose to purchase a transformer that matches the production capacity based on the equipment power provided by the equipment manufacturer.

(5).Clear scale and budget: Medium-sized and large biomass pellet plants usually refer to plants with an annual production capacity of 50,000 to 100,000 tons. The initial investment is about USD70,000 or more, depending on the equipment selection, plant size and regional differences, and also covers land acquisition, equipment procurement, plant construction, personnel recruitment and training, operating funds, etc. It is recommended to reasonably plan production capacity according to the funding situation, give priority to ensuring the quality of core equipment (such as biomass pellet machines, rotary dryers, wood crushers), and avoid affecting long-term production efficiency due to low-price purchases.

(6).Team building and technical training: A professional project team is formed, including engineers, technicians, managers, etc., to be responsible for all aspects of the factory's design, construction, and operation. In addition, relevant technical training is provided to team members to improve their professional skills and operational level, laying the foundation for the smooth operation of the factory.

2. Equipment Procurement, Installation and Commissioning

(1). Core process flow and equipment selection

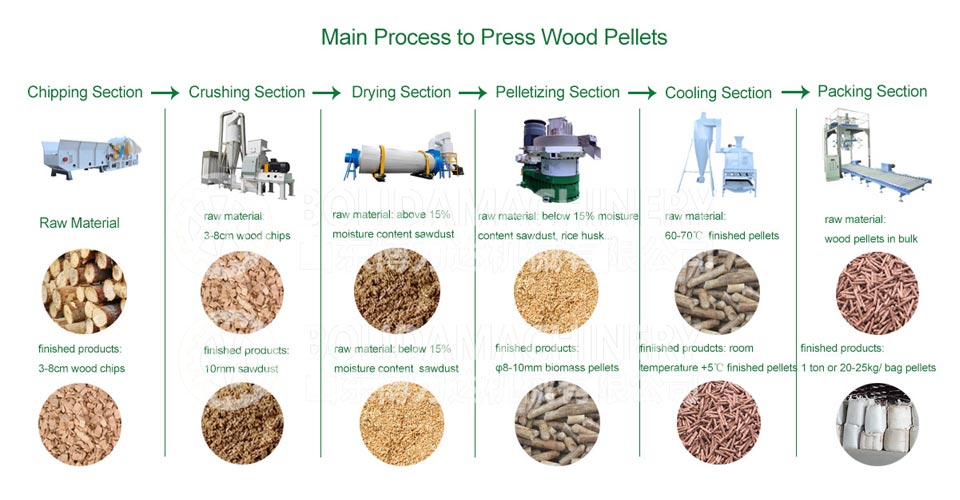

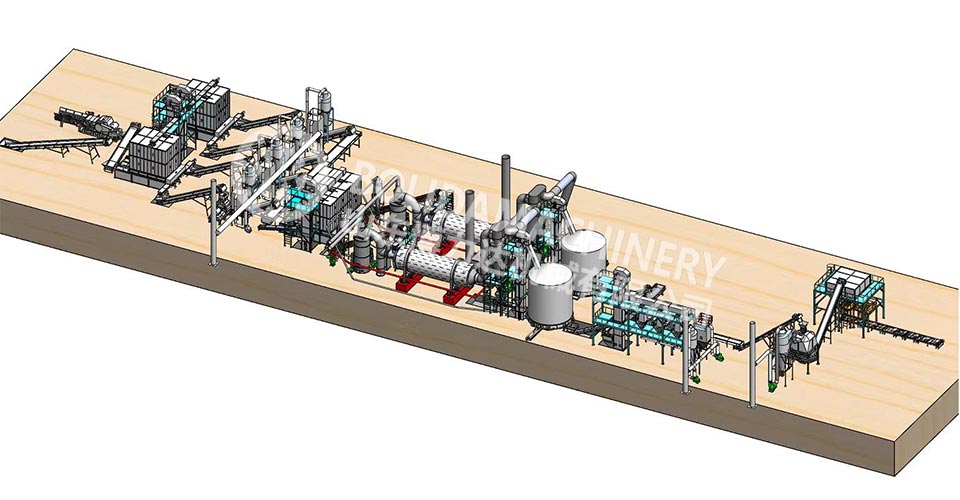

Medium and large factories need to be equipped with the following complete processes:

Raw material pretreatment: The wood chipper crushes the wood to into <5cm smaller chips, and screens out impurities.

Crushing: The small wood chips are further crushed to sawdust within 10mm.

Drying: The biomass rotary dryer reduces the moisture content of the raw materials to 12%-15%.

Pelletizing: The high-pressure pellet machine is extruded by a die, and temperature control is the key.

Cooling and packaging: After pelletized, the automatic packaging machine packs them into bags or bulk.

Other auxiliary equipment: conveyor equipment, storing equipment, electric control system...

(2). Automation system configuration: In order to improve production efficiency, reduce labor costs and reduce human errors, investors with conditions are recommended to configure an automation control system in the factory, such as a PLC control system, to achieve real-time monitoring, data collection and automatic adjustment of the production process, making production more intelligent and efficient.

(3). Equipment installation and commissioning: After the equipment arrives at the factory, our professional installation team will guide the workers according to the design drawings and operating specifications. After the installation is completed, single-machine debugging and linkage debugging are carried out to ensure that the various devices work together, the production process is smooth, and various technical indicators meet the expected requirements.

3. Investment and Cost Control

(1). Main investment composition

| Project | Remarks |

| Plant construction | Including land, infrastructure and environmental protection facilities |

| Equipment procurement | According to the specific configuration of the project and the equipment situation |

| Raw material reserves | According to local raw materials |

| Operational costs | Including manpower, energy consumption and maintenance |

Raw material diversification: Mix low-priced raw materials such as sawdust and straw to balance seasonal supply fluctuations. Do well in raw material collection and transportation: According to the raw material supply plan, organize vehicles and personnel to collect biomass raw materials, such as wood waste, crop straw, etc. from the raw material supply area, and transport them to the factory. During transportation, pay attention to the protection of raw materials to avoid moisture, pollution, etc.

Utilization of government subsidies: Pay attention to the biomass energy subsidy policies of various countries to reduce initial investment.

4、Production and Quality Control

(1). Standardization of production process: Develop detailed production process and operation specifications, covering every link from raw material input to finished product packaging. Employees must strictly follow the process and specifications during the operation to ensure the consistency and stability of product quality.

(2). Quality inspection and control: Establish a strict quality inspection system, conduct regular sampling inspections on semi-finished products and finished products in the production process, and the inspection items include key indicators such as pellet density, moisture content, ash content, calorific value, etc. Once quality problems are found, take timely measures to adjust and improve to ensure that the pellets shipped meet relevant quality standards and customer needs.

(3). Production data recording and analysis: During the biomass pellet production process, record various production data, such as equipment operating parameters, raw material consumption, product output and quality data. By analyzing these data, bottlenecks and problems in the production process can be found, providing a basis for optimizing production processes, improving production efficiency and product quality.

5. Environmental Protection and Compliance Requirements

(1). Waste gas treatment: A certain amount of waste gas will be generated during biomass pellets production, and corresponding environmental protection treatment facilities need to be equipped to ensure that the waste gas meets the emission standards and reduce pollution to the environment.

(2). Noise control: The production equipment in the factory will generate noise pollution, and effective noise control measures should be taken, such as installing shock-absorbing pads, sound insulation covers, etc., to reduce the impact of noise on the surrounding environment and employee health.

(3). Safety production management: Establish and improve the safety production management system, strengthen safety training and education for employees, and improve employees' safety awareness and operating skills. Set up obvious safety warning signs in the factory, equip with complete fire-fighting facilities and emergency rescue equipment, conduct regular safety inspections and hidden danger inspections to ensure the safety and reliability of the production process.

(4). Compliance operation: Comply with local laws, regulations and industry standards, handle relevant business licenses, environmental protection licenses, safety production licenses and other procedures, and ensure the legal and compliant operation of the factory.

(5). Certification and export qualifications: Obtain FSC (Forest Stewardship Council) certification and ISO 9001 quality management system to meet international market access conditions.

The construction of medium-to-large biomass pellet plants requires consideration of technology, cost and market strategy. Choosing reliable equipment suppliers, optimizing production processes, and keeping up with international environmental protection policies will significantly improve the return on investment. If you need customized your biomass pellet plant solutions or biomass pellet production line equipment selection support, please contact the Bolida&Rotexmaster professional team for one-stop service.

Full analysis of raw materials for biomass pellets in Thailand

Mar. 21, 2025

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log