The wood chipper machine is mainly used to cut wood log. It can also process wood chips so that wood chips can be used in actual production. In order to improve production efficiency, it is necessary to increase the output of the equipment. What are the main methods?

1. When you just bought it back, when it is feeding normally, the feeding is slow, you need to use your hand to press it inside to be able to better process and use. Turn on the wood chipper, then use a ruler to measure, adjust the blades of the wood chipper machine to the outside, about three or four millimeters, and then adjust each blade the same.

2. The processing speed of the wood chipper machine becomes slow after being used for a period of time. Take off the blade, sharpen it, and replace it for normal processing.

3. After the blade is processed, the processing efficiency is still very low, that is, the blade is worn out, and it will not work soon after grinding. In this case, the machine blade needs to be replaced.

Therefore, if you want to increase the output of the wood chipper, you can adjust the blade appropriately, sharpen the blade to increase its sharpness. Besides, you need replace the blade, which can increase the output of the equipment and is also beneficial to the maintenance of the equipment.

What are the key factors influencing forming of wood pellets

Mar. 21, 2025

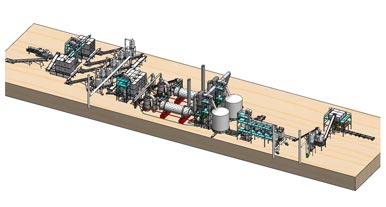

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log