During the use of the wood pellet machine, it is necessary to regularly maintain the wood pellet machine to make it work normally, and also to protect and maintain the power system of the pellet machine regularly to avoid failures and ensure the smooth operation of the motor. How should the motor be maintained?

1. Always clean up the oil and dust on the motor. If the operating environment is harsh and the dust is relatively large, it is recommended that we regularly clean the motor every few days to ensure that the motor is cleaned and works smoothly.

2. Check the couplings of the transmission parts of the equipment to see if some of the couplings are flawed or damaged. The damaged couplings will cause many dangers, so they can be replaced in time, which effectively avoids many accidents.

3. Check the position of the fixed screws to see if they are loose. If it is loose, stop working, and the staff will fasten it in time to avoid accidents.

4. After the bearing used for a period of time, it should be sorted out in time, and the lubricating grease and mechanical oil should be replaced. The frequency of sorting and replacement should be determined according to the working time of the motor. The general replacement frequency should be sorted and replaced lubricating grease and machine oil after the motor works for about half a year.

When we use the wood pellet machine, we must maintain its motor, because the motor is the driving force for driving the equipment. Once damaged, the equipment will not be able to run. Therefore, it is necessary to master some methods of maintaining the pellet machine motor.

Mar. 21, 2025

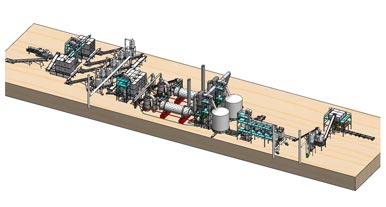

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log