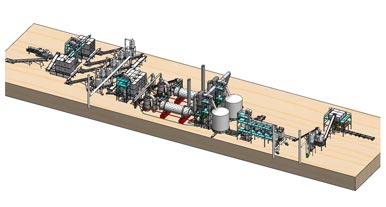

Investing in a wood pellet production line project is divided into several steps, generally in three steps. Pre-preparation stage, mid-term equipment inspection stage, and post-production and sales stage. Below Rotexmaster will explain the three stages in details.

The first stage of preparation

1. Raw materials. Whether raw materials are sufficient is a key issue in the pellet industry. Some people think that there are a lot of raw materials around them, so there is no need to investigate, they are wrong. It is not only necessary to inspect but also focus on these points: the type of raw materials, the size of raw materials, the moisture content of raw materials, and the amount of raw materials.

In fact, there are many raw materials that can be used to make biomass pellets, such as corn stalks, wood chips, bamboo chips, rice husks, furniture factory scraps, and building templates.

2. Plant and transformer. These two hardware facilities are indispensable, especially for transformers. Biomass energy belongs to the energy-consuming industry. The smallest wood pellet machine is 90KW, plus other equipment, the whole wood pellet production line with an output of 1 ton per hour must be driven by a transformer with a minimum of 130 kVA.

3. Investment budget. First of all, let me explain that the threshold for this industry is a bit high. Some small manufacturers offer wood pellet production line with cheap price, which must be fooling people. Warmly remind everyone not to be fooled!

The second step is the equipment inspection stage

If the above three: raw materials, factory plant, transformers, and budget are all ready, then you can choose the manufacturer to inspect the equipment.

ready.

Please Pay attention

1. Choose a reliable wood pellet production line manufacturer. Inspect more, be sure to make on-the-spot inspections to see the production capacity and after-sales guarantee of the manufacturer.

Don't blindly listen to what they said, and when necessary, you can bring raw materials to test the wood pellet machine.

2. To select biomass wood pellet production line according to the material, it is necessary to determine the moisture, size and output of the raw material, etc., based on the actual situation.

3. Project design. Each manufacturer will provide you a set of plans according to the size of your site and the equipment you need, choose a few more manufacturers, and make more comparisons.

4. Don't be greedy for cheap and suffer big losses. In terms of equipment, you must choose good quality and good service, otherwise the equipment will not run smoothly in the later stage, and you will lose a lot of money!

The third step is the production and sales stage

1. After selecting the manufacturer and setting the wood pellet production line, we will have professional after-sales technicians to guide the installation and debugging, and train the workers how to operate the wood pellet production line. If the equipment is well learned and used well, the output is not only high, but the equipment is not out of order.

2. Inspect the local pellet market, such as coal-fired enterprises, power plants, clothing factories, etc. to get such pellets.

Mar. 21, 2025

How to build a medium-large scale biomass pellet plant: key steps and Investment guideline 20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log