Model: YLQJ1.5; YLQJ2.5; YLQJ4; YLQJ6; YLQJ10

Capacity: 1-2t/h; 2-4t/h; 4-6t/h; 6-8t/h; 8-10t/h

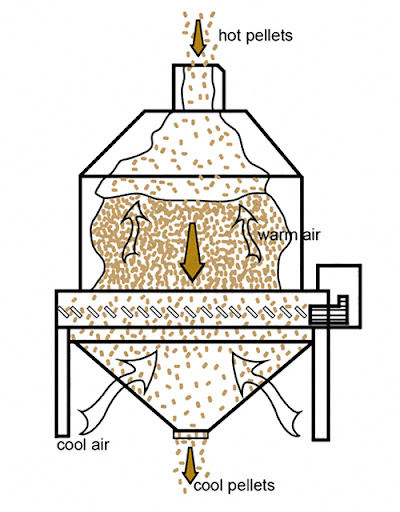

The counter flow cooler is a new type of cooler that is currently internationally advanced; Pellet cooler mainly cools high-temperature 60-80 ℃ biomass pellets, and the temperature after cooling is not higher than room temperature +3-5.

It adopts the counter-current principle to cool high-temperature and high-humidity materials. The natural wind enters the cooler from bottom to top, and the hot wood pellets enters the cooler from top to bottom. The natural wind passes through the material layer vertically and first contacts the material. The wood pellets are gradually cooled to avoid cracking on the surface of the pellets due to the sudden cooling. The air fully enters the cooler from the bottom, the entering area is large, so wood pellets can be fully and uniformly cooled.

Pellet cooler is generally used in conjunction with cyclone, fan, and air lock, which is used to absorb cold air and cleaning dust. A simple screener can also be installed at the bottom of the cooler to separate powdered dust and good pellets.

| Model | YLQJ1.5 | YLQJ2.5 | YLQJ4 | YLQJ6 | YLQJ10 |

| Power(kw) | 0.25+1.5+1.5+7.5 | 0.37+2.2+1.5+11 | 0.55+3+1.5+22 | 0.75+3+2.2+37 | 0.75+3+3+45 |

| Capacity(kg/h) | 1-2 | 2-4 | 4-6 | 6-8 | 8-10 |

1. Pellet cooler mainly cools high-temperature and high-humidity materials, after cooler, the temperature is not higher than room temperature +3-5.

2. Counter flow theory ensures that wood pellets can be cooled fully and uniformly. pellet broken rate is smaller than 0.2%.

Q: Are you manufacturer or trading company?

Q: I am newer to biomass industry, how to design suitable pellet plant?

Q: How to prepare for setting up a wood pellet production line?

Q: How can you guarantee the after-sales service?

Q: Are there some machines in my area I can observe?

Q: What type of raw materials can be pelletized by RotexMaster pellet machine?

Q: How to confirm the compression ratio of mould for my raw material?

Q: What is the main process for making biomass pellets?

Q: What is your work flow if we order Rotexmaster equipment?

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.